Creating a 1000 MPH Wheel

The wheels for Aussie Invader 5R were conceived and designed by LSR engineering legend John (Ackers) Ackroyd, with input from many highly respected engineering professionals and companies.

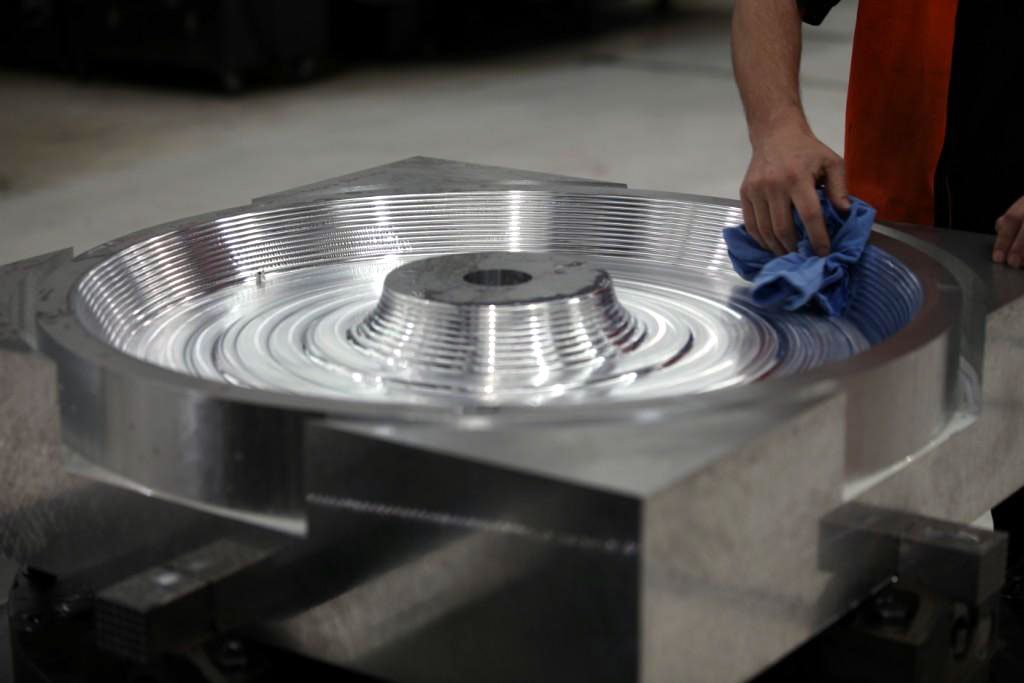

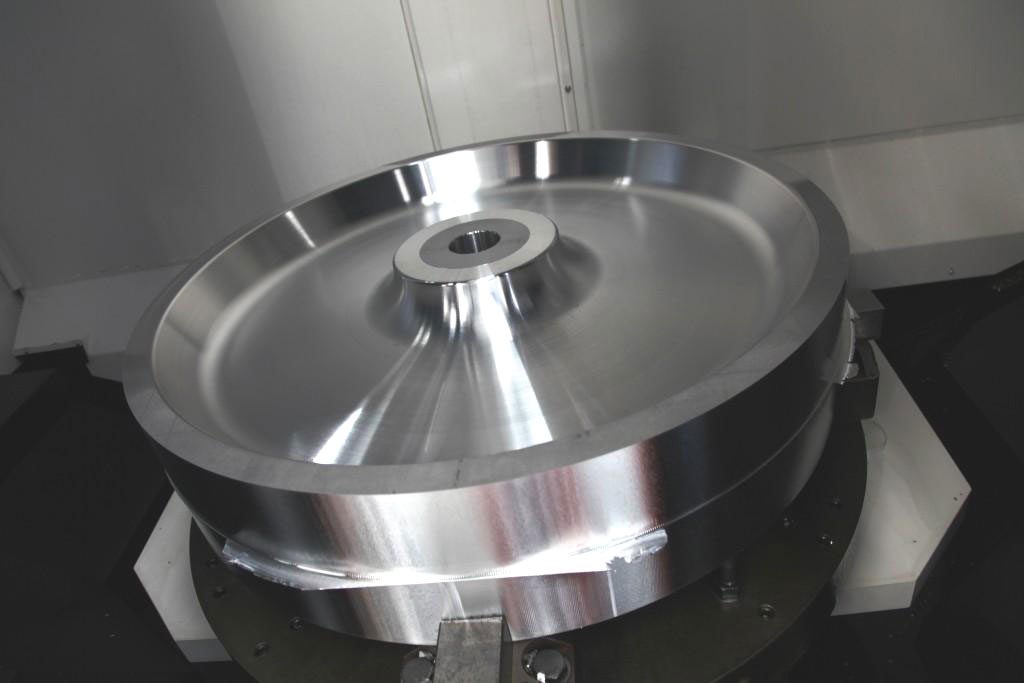

Aussie Invader 5R will run on four solid Calm Aluminium tyreless wheels, with each wheel spinning independently. The front two wheels are side by side with a 30 mm spacing. The wheel profiles vary slightly due to different car weight bias from front to rear. The front wheels have a more rounded profile, with the rear wheels being more “V” shaped.

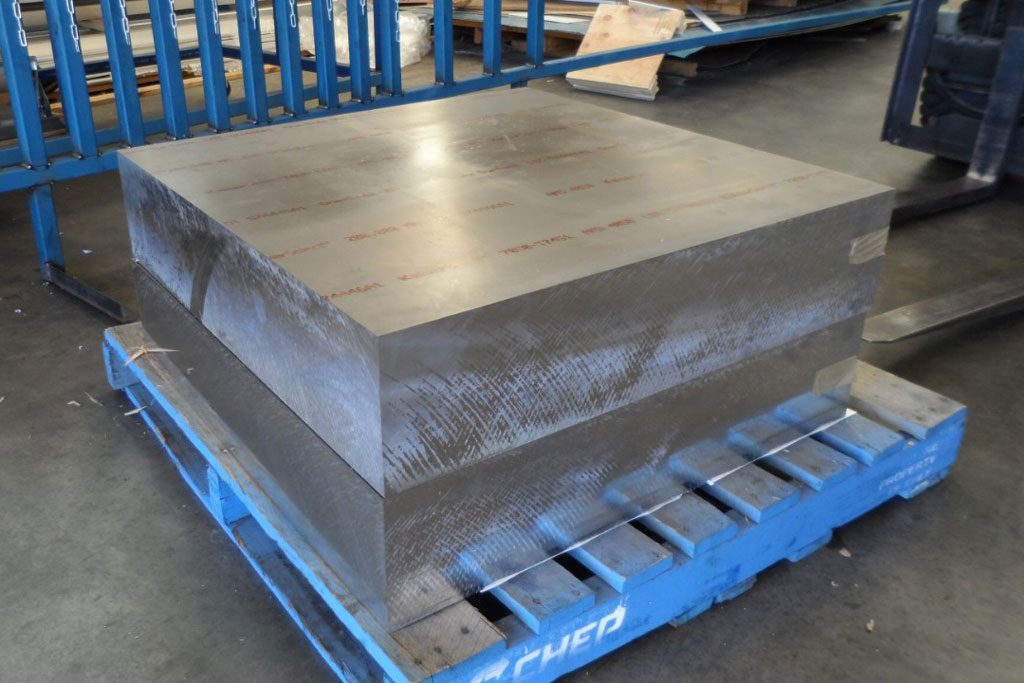

The wheels for Aussie Invader 5R are the culmination of many years work by Rosco and the team and were expertly machined by VEEM who are one of Western Australia’s top engineering companies, known for its precision work in the Defence, Marine, Transport, Mining, Oil and Gas fields.

Sponsor: Calm Aluminium

Material: Machined from 7050 billet alloy

Weight: 140kg per wheel

Dimensions: 900mm diameter x 198mm wide

Maximum rotational speed: 10,000 RPM +/- 5%

Preparation: Shot peened, balanced and spun tested

Force at wheel rim: 50,000 G at 1000 mph/1600+ km/h

Bearing type: SKF 7020 ACD/P4AQBCA series angular contact

Bearings per wheel: 4

Wheel profiles: Different due to car weight bias from front to rear

The wheels are designed to race on an alkali mud lake surface where they will achieve a higher drag co-efficient than on salt, allowing Aussie Invader 5R to accelerate at a constant 3G and on to 1,000 mph (1,600+ km/h).

The Bearings